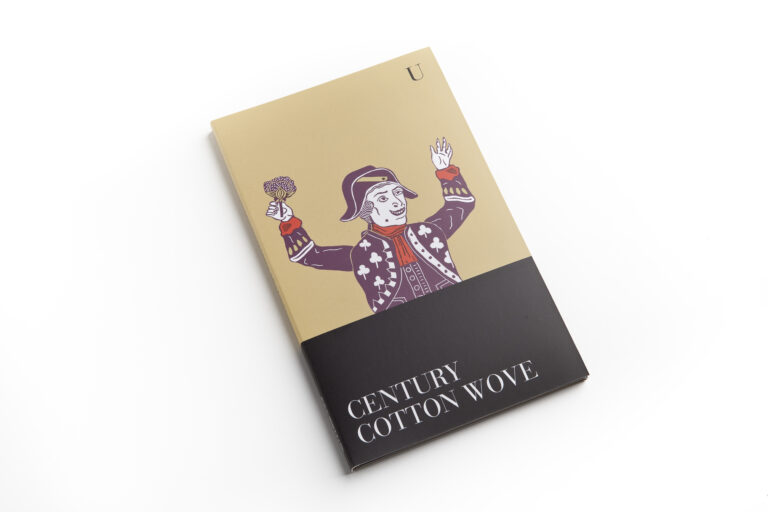

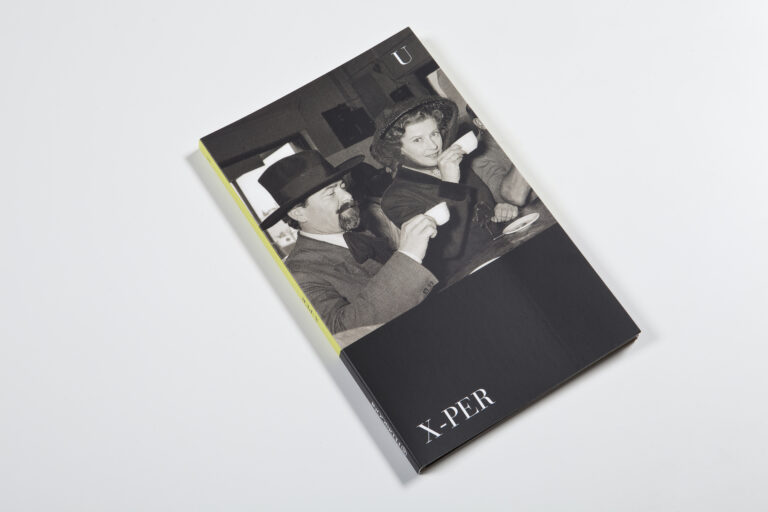

Some people call it the Swiss army knife of natural, white and ivory papers. The natural companion to any printed story.

Smooth or rough, available in four different shades, from bright Ivory to Extra White without whitening agents, in various sizes and weights (from 70 to 580 g/m2) to adapt to all printing processes: offset, hot foil stamping and embossing.

A multifunctional cardboard series suitable for any graphics project. It’s not just simple: it’s perfect.

Find ARENA on page 29 of PaperBox, volume UNCOATED WHITES.

Brand Series:

Arena Bulk

Arena Smooth

Arena Rough

Arena Eco 50

Arena

Fedrigoni Arena® is range of white and ivory uncoated papers and boards for every need and for every specifer. The Arena range is available in four shades: a bright Ivory, on OBA-free Natural, a warm White and a cool Extra White in a wide choice of sheet sizes, grain directions and grammages. Arena is available in three finishes: Smooth, Rough and Bulk. A selection of HP Indigo® optimized papers and matching envelopes complete the range. Fedrigoni Arena® is a multi-functional tool for any graphic project.

Rational yet elegant, good for text, photography, packaging and illustrations, it works with any printing and post-printing process and performs well with any binding and folding technique.